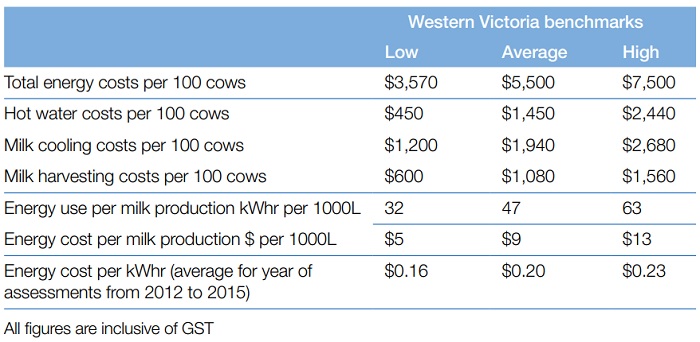

Heating water accounts for approximately 25% of total how water demand of a dairy farm. According to Dairy Australia, water heating is the second biggest energy cost after milk cooling costs.

Hot water in dairy farms is needed for washing milking machines, bulk tanks and parlor equipment.

Water temperature and amount of water

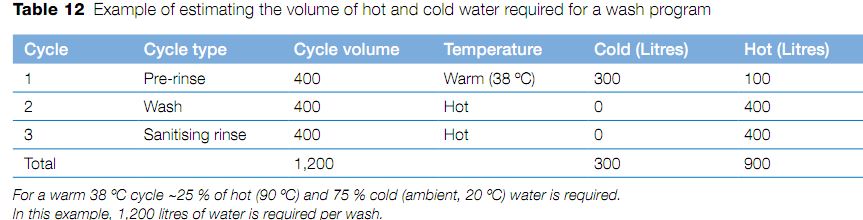

The following table from Australian Dairy Hygiene hanbook shows typical amoun of water used and the temperatures.

Referring to the above, in average, hot water temperature used in a typical dairy farm daily cycle is 72.5C. This is composed of 900 litres of hot water at 90C and 300 litres cold water at 20C.

Cost efficient energy sources for heating hot water

For water to be heated up from 20C from mains up to 90C, different free and renewable energy sources can be used to heat up water depending on their availability. Renewable energy systems are most efficient and provide the most cost saving at low temperature. This is crucial to let them heat water from 20 to 60 degrees and us conventional electric element heater to heat the water from 60 to 90C.

Solar thermal or solar hot water

solar hot water provides free heating energy from sun. Sun heat solar hot water absorber plates and heat is transferred to circulating water from storage tank.

Heat recovery

Desuperheater can be installed in your refrigeration system for cooling milk that can provide free heat to heat your hot water that other wise would have been wasted to ambient.

A desuperheater is refrigernat to water heat exchanger, that allows passing heat from hot refrigenrat to your hot water tank.

Pros: As the source of energy is free heat from your cooling system, it can be considered a cost effective energy upgrade.

Cons: It is only available when cooling system is in operation. regular inspection is required to make sure no refrigerant can leak into water cycle or vice versa.

Water to water heat pump

A water to water heat pump is far more efficient that the heat recovery system as it has much bigger heat exchanger allowing to simultaneous heat hot water and cool the milk. part of hot water demand and Milk cooling can occur simultaneously and thus this solution can cover part of hot water heating and cooling process very cost effectively.

Heat pump efficiency rating

sizing water heater

The best approach to sizing your system components including heat pump water heater and milk cooler is to look into to your hour by hour energy demand.

Reducing standby losses

Hot water tanks can loose a lot of heat to ambient. Best solution is to install them indoors to minimize air speed on their skin and minimize heat losses.

For more information

Search our website for further information on different technologies and other energy cost saving opportunities. We have a lot of articles that cover most of the items that we charge to deliver in our project specific energy audit and feasibility assessment. Otherwise, give us a call and we will try to assist with as much as possible.